About the Consortium for Future Innovation by Cultured Meat

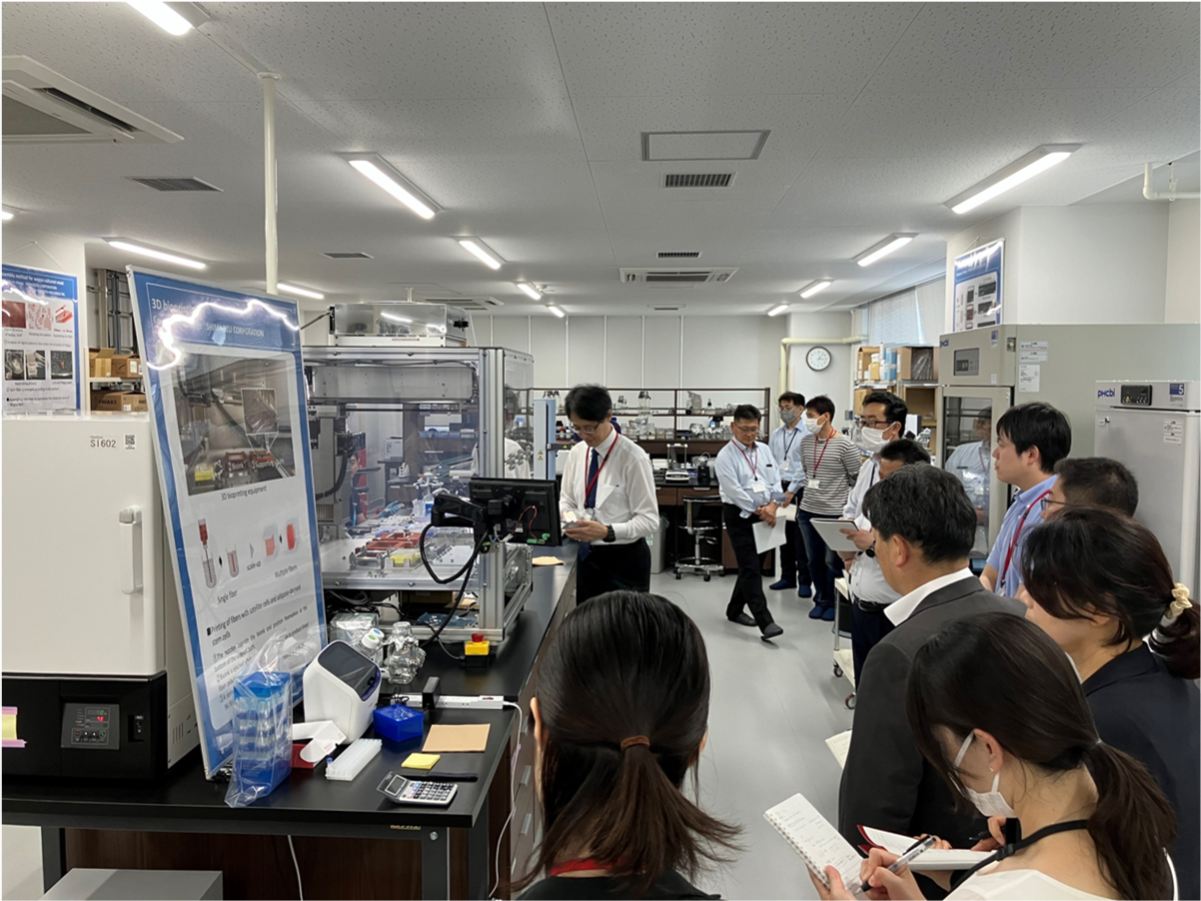

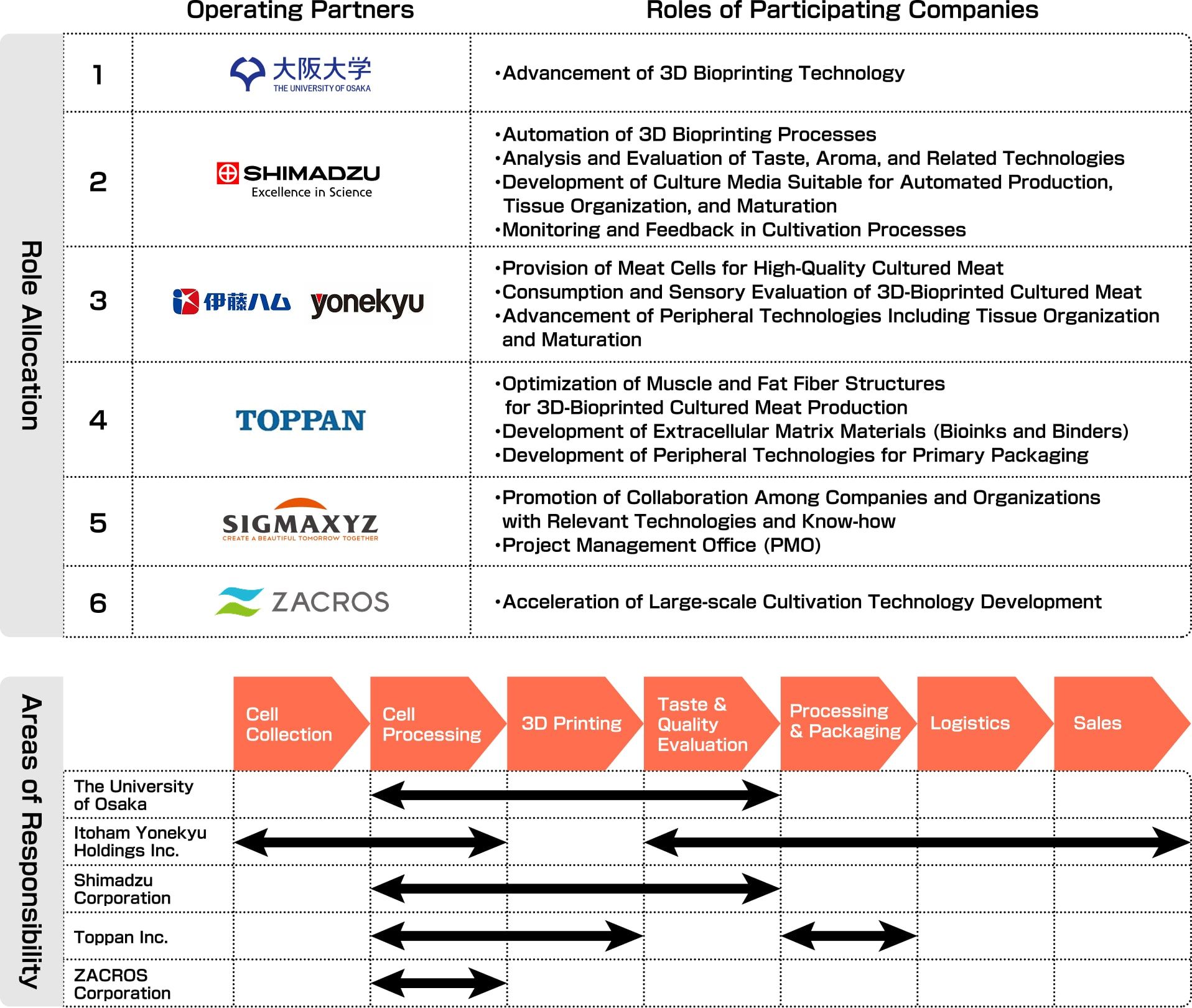

On March 29, 2023, the Graduate School of Engineering at Osaka University (hereinafter referred to as "Osaka University"), Shimadzu Corporation (hereinafter referred to as "Shimadzu"), Itoham Yonekyu Holdings Inc. (hereinafter referred to as "Itoham Yonekyu"), Toppan Printing Co., Ltd. (now TOPPAN Holdings Inc.; hereinafter referred to as "TOPPAN"), and SIGMAXYZ Inc. (hereinafter referred to as "SIGMAXYZ") established the "Consortium for Future Innovation by Cultured Meat." Subsequently, on May 8, 2024, ZACROS Corporation joined the initiative. The consortium is now being driven forward with six core member companies.

The purpose of this consortium is to promote practical initiatives for the social implementation of 3D bioprinted cultured meat production technology. We aim to advance collaborative development across companies in areas such as the application of 3D bioprinting technology and the establishment of an integrated value chain covering production and distribution. Furthermore, to achieve widespread social adoption, we are also working on the development of large-scale culturing technology and the establishment of a stable cell production process, with the goal of commercializing cultured meat by 2031.

As a platform for globally sharing our consortium’s activities, we will participate in the Osaka Healthcare Pavilion at the 2025 Osaka-Kansai Expo, which is sponsored by Osaka Prefecture and Osaka City. At this pavilion, we plan to showcase future automated cultured meat production and 3D bioprinted cultured meat, presenting cultured meat as one of the "Foods of the Future" that can reduce environmental impact and help address the global protein shortage.

Through the activities of this consortium, we are committed to contributing to solutions for environmental and food-related challenges, promoting public health, and proposing a new vision for the future of food.

Courtesy of the EXPO 2025 Osaka Pavilion Association

About Cultured Meat

Potential and Expectations for Cultured Meat

Cultured meat has gained attention as a potential solution to medium- and long-term protein shortages and environmental issues. In conventional livestock farming, the increasing global population is expected to drive higher demand for meat, making it difficult to maintain a sufficient supply. This raises concerns about potential protein shortages in the future. Furthermore, the environmental impact of livestock farming, including greenhouse gas emissions, has been widely recognized as a critical issue.

In contrast, cultured meat is produced from animal cells in a controlled laboratory environment, reducing resource consumption and minimizing environmental impact. As a result, it is expected to serve as a sustainable protein supply method with a significantly lower ecological footprint compared to traditional livestock production.

Real Meat-like Structure is Key

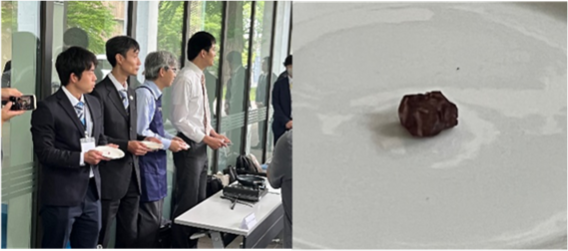

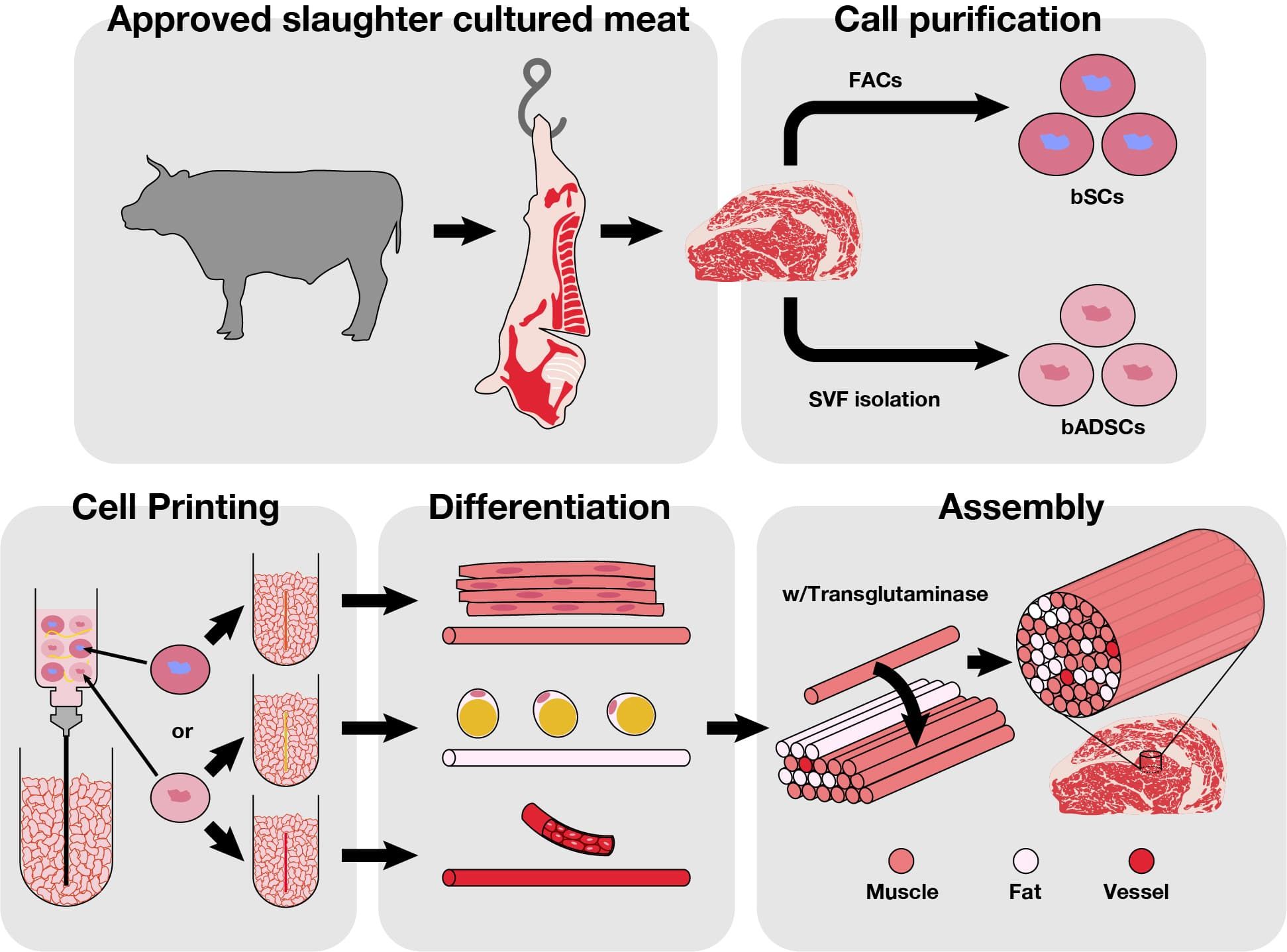

Our cultured meat production begins with the extraction of a small tissue sample from bovine tissue. After isolating muscle, fat, and vascular cells, we culture and expand them separately. Using a 3D printer, these cells are then formed into fibrous strands less than 1 millimeter in diameter. By bundling these strands together, we can create marbled beef (steak meat), with the ratio of muscle to fat freely adjustable.

Currently, the manually assembled pieces remain under 1 millimeter in size. However, despite their small scale, they retain the essential structure of real meat, which is a key advantage of this method. Additionally, this technique is highly adaptable, making it suitable for use with not just cattle, but also other animals and fish, broadening its potential uses in the cultured meat industry.

Towards Healthier and Tastier Cultured Meat

Moving forward, this consortium aims to advance technologies for flavor and nutritional control to provide healthier and more delicious cultured meat. In addition, by automating the production process through corporate collaboration and establishing a supply chain, we plan to scale up cell production and achieve the commercialization of cultured meat by 2031.

Through these efforts, we expect to contribute to a sustainable food supply and a reduction in environmental impact, helping to address global food challenges in a responsible and innovative way.

About the Consortium

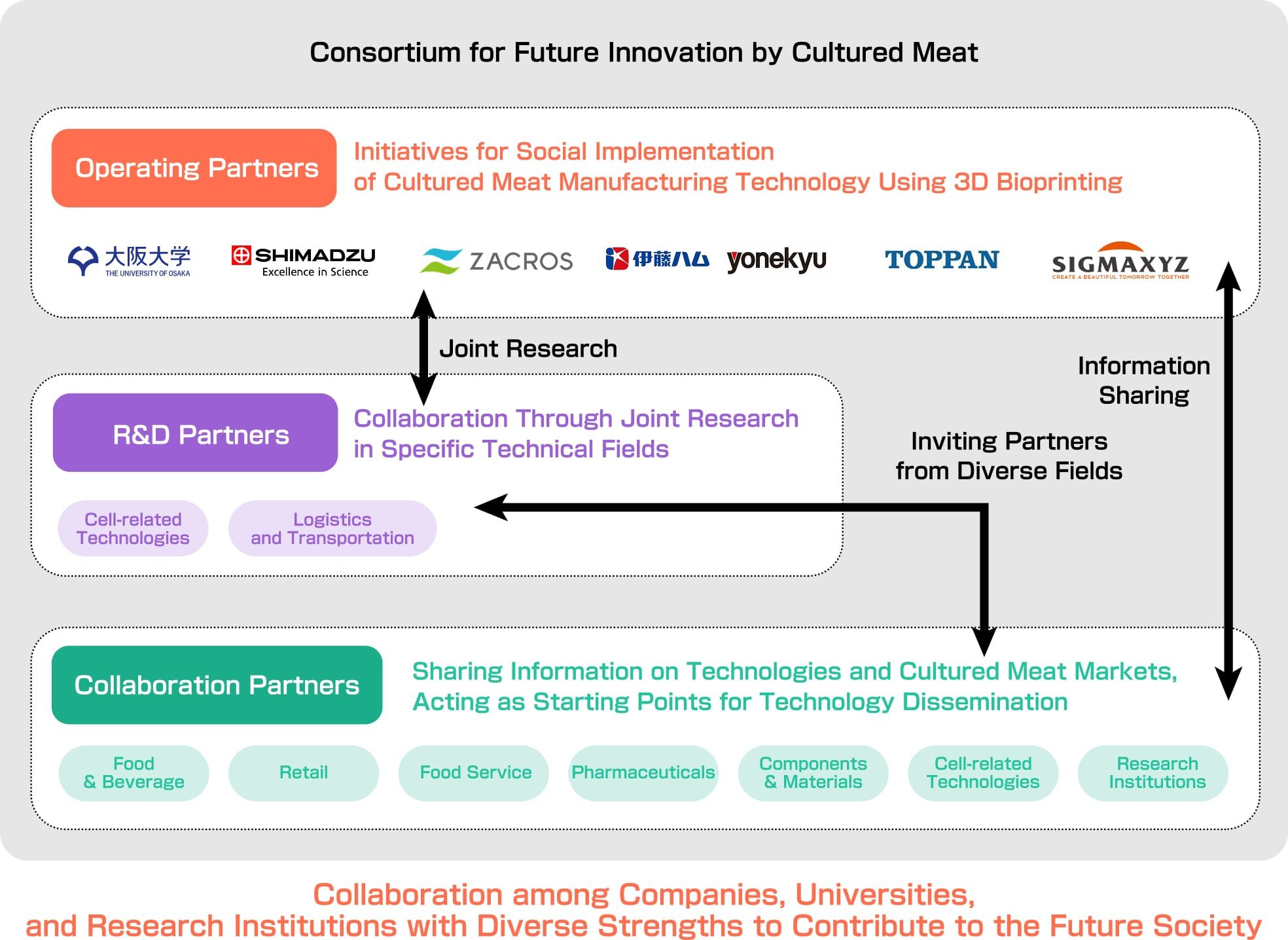

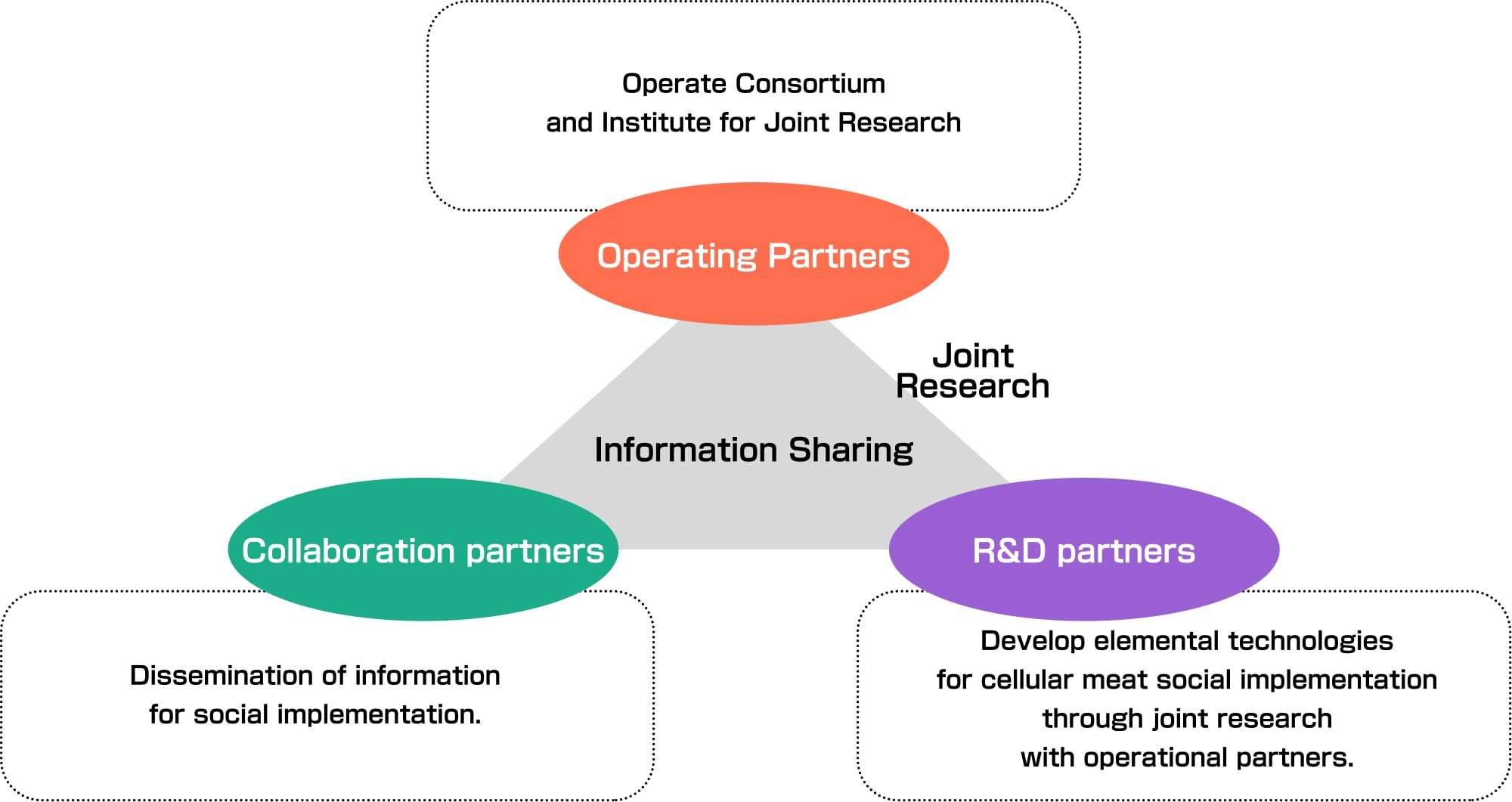

3 types of partners

The consortium is led by six core operating partners, who drive joint research and technology development. In addition, we are actively seeking R&D partners to collaboratively develop technologies for social implementation and collaboration partners to promote the widespread adoption of these technologies.

By fostering information sharing and strengthening cooperation among these partners, we aim to accelerate the social implementation of cultured meat technology and its broader market adoption.

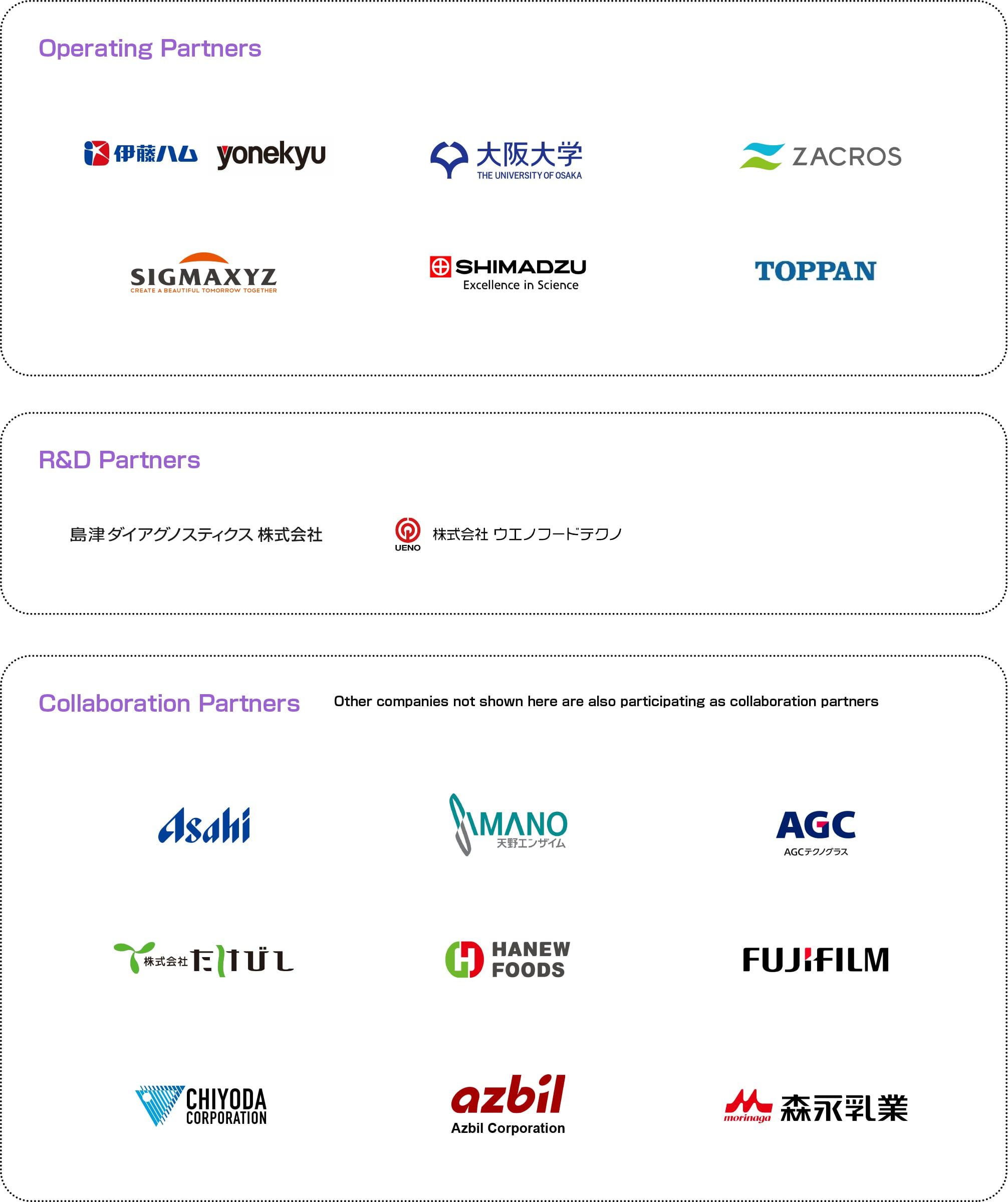

Participating Companies

As of now, the consortium comprises six operating partners: Itoham Yonekyu Holdings Inc., Osaka University, ZACROS Corporation, SIGMAXYZ Holdings Inc., Shimadzu Corporation, and TOPPAN Holdings Inc. Additionally, there are 12 organizations participating as R&D and collaboration partners, bringing the total number of participating organizations to 18, including the operating partners.

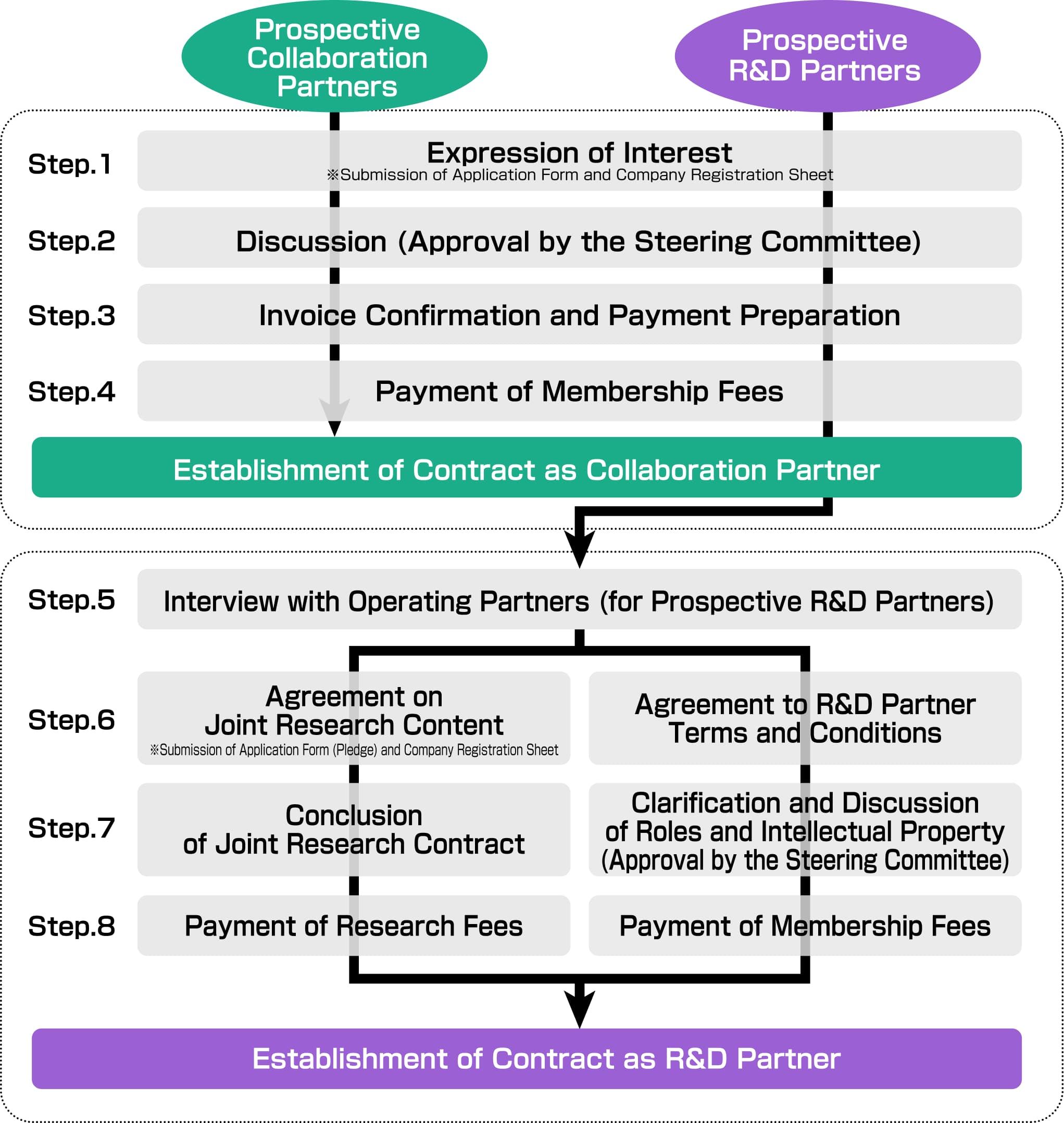

How to join the consortium as a parter

Collaboration Partner

- 1.Consortium Briefing Meeting (Conducted as needed)

- 2.Receive Required Documents from the Consortium

①Membership Application Form

②Company Registration Sheet

③Terms and Conditions - 3.Submit ① and ② to the Consortium Secretariat

- 4.Receive Invoice from the Consortium

- 5.Membership is confirmed upon payment and verification by the Consortium.

R&D Partner

Note: Companies applying as R&D partners must first join as collaboration partners.

- 1.Complete Steps 1–5 of the Collaboration Partner Process

- 2.Discuss Research Themes

- 3.Refine Research Themes & Fill Out Research Theme Sheet

- 4.Submit Research Application Form

- 5.Establish Joint Research Agreement with Osaka University (Each company must review the contract individually)

- 6.R&D Partner status is granted upon signing the Joint Research Agreement and confirmation by the Consortium."

Join the Consortium

The 'Consortium for Future Innovation by Cultured Meat' welcomes the participation of companies and organizations dedicated to developing cutting-edge technologies, and promoting the social implementation of sustainable future foods. We seek partners to collaborate in technological innovation, supply chain development, and the creation of a new future for food.

Join us in taking the next step toward realizing environmentally friendly and health-conscious cultured meat. Let’s work together to shape the future of sustainable food.